Sankhani ku: Zopangira ma gearbox amtundu wapawiri-clutch ndizonyowa ziwiri-clutch gearbox, chipolopolo chothandizira chimakhala ndi chipolopolo cha clutch ndi gearbox, zipolopolo ziwiri zomwe zimapangidwa ndi njira yoponderezedwa kwambiri, popanga chitukuko ndi kupanga zidakumana ndi zovuta kukonza zinthu. , 60% 95% pofika kumapeto kwa kukwera kwa 2020, Nkhaniyi ikufotokoza mwachidule mayankho azovuta zamakhalidwe abwino.

Kutumiza konyowa kwapawiri-clutch, komwe kumagwiritsa ntchito zida zatsopano za cascade, makina oyendetsa ma electro-mechanical shift drive system ndi cholumikizira chatsopano cha electro-hydraulic clutch. Chopanda chipolopolocho chimapangidwa ndi aloyi ya aluminiyamu yothamanga kwambiri, yomwe imakhala ndi kulemera kopepuka komanso mphamvu zambiri. Pali pampu ya hydraulic, mafuta opaka mafuta, chitoliro chozizira komanso makina ozizira akunja mu bokosi la gear, zomwe zimayika patsogolo zofunikira pamakina onse komanso magwiridwe antchito a chipolopolo. Pepalali likufotokoza momwe mungathetsere zovuta zamtundu monga kupindika kwa zipolopolo, dzenje la mpweya wocheperako komanso kuchuluka kwa kutsika komwe kumakhudza kwambiri kuchuluka kwa opambana.

1,Njira yothetsera vuto la deformation

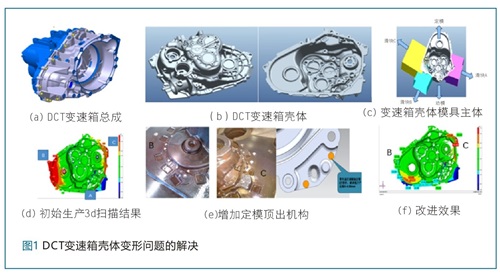

Chithunzi 1 (a) pansipa,Bokosi la giya limapangidwa ndi nyumba zokhala ndi zotayira zotayidwa komanso zowawalira. Zomwe zimagwiritsidwa ntchito ndi ADC12, ndipo makulidwe ake oyambira ndi pafupifupi 3.5mm. Chigoba cha gearbox chikuwonetsedwa mu Chithunzi 1 (b). Kukula koyambira ndi 485mm (kutalika) × 370mm (m'lifupi) × 212mm (kutalika), voliyumu ndi 2481.5mm3, malo omwe akuyembekezeredwa ndi 134903mm2, ndipo kulemera kwake ndi pafupifupi 6.7kg. Ndi mbali yopyapyala yokhala ndi mipanda yakuya. Poganizira zaukadaulo wopanga nkhungu, kudalirika kwa kuumba kwazinthu ndi kupanga, nkhunguyo imakonzedwa monga momwe tawonetsera pa Chithunzi 1 (c), chomwe chimapangidwa ndi magulu atatu a slider, kusuntha nkhungu (kunjira yakunja). patsekeke) ndi nkhungu yokhazikika (molowera mkati mwamkati), ndipo kuchuluka kwa kutentha kwaponyedwe kumapangidwa kukhala 1.0055%.

Kwenikweni, poyesa kuyesa koyambirira kwa kufa, zidapezeka kuti kukula kwake kwa chinthu chopangidwa ndi kufa kunali kosiyana kwambiri ndi zomwe zidapangidwa (maudindo ena anali opitilira 30%), koma kukula kwa nkhungu kunali koyenera ndipo kuchuluka kwa kuchepa poyerekeza ndi kukula kwenikweni kunalinso kogwirizana ndi lamulo la shrinkage. Pofuna kudziwa chomwe chayambitsa vutoli, 3D scanning ya chipolopolo chakuthupi ndi theoretical 3D idagwiritsidwa ntchito poyerekezera ndi kusanthula, monga momwe tawonetsera pa Chithunzi 1 (d). Zinapezeka kuti m'munsi malo malo opanda kanthu anali wopunduka, ndi kupunduka kuchuluka anali 2.39mm m'dera B ndi 0.74mm m'dera C. pokonza malo benchmark ndi kuyeza benchmark, mapindikidwe izi kumabweretsa mu muyeso, zina kukula ziyerekezo kwa A, B, C monga maziko a ndege, malo dzenje ndi kunja dongosolo.

Kusanthula zomwe zimayambitsa vutoli:

①High pressure casting die design Mfundo ndi imodzi mwazinthu zomwe zidapangidwa pambuyo pobowoleredwa, zomwe zimapatsa mawonekedwe amtundu wosinthika, zomwe zimafunikira kuti mphamvu yamphamvu ya phukusi ikhale yayikulu kuposa mphamvu zomwe zimagwira pa thumba lokhazikika lokhazikika, chifukwa cha zakuya patsekeke wapadera mankhwala pa nthawi yomweyo, patsekeke kwambiri mkati mwa mitima pa anakonza nkhungu ndi kunja patsekeke anapanga pamwamba pa kusuntha nkhungu mankhwala kusankha malangizo a nkhungu kulekana pamene mosalephera kuvutika kukokera;

②Pali zotsetsereka kumanzere, kumunsi ndi kumanja kwa nkhungu, zomwe zimagwira ntchito yothandiza pakumangirira musanapangidwe. Mphamvu yocheperapo yothandizira imakhala kumtunda kwa B, ndipo chizolowezi chokhazikika ndikukhazikika m'bowo panthawi ya kutentha. Zifukwa ziwiri zomwe zili pamwambazi zimapangitsa kuti pakhale kusintha kwakukulu pa B, kutsatiridwa ndi C.

Chiwembu chowongolera kuti athetse vutoli ndikuwonjezera njira yolumikizira kufa yokhazikika Chithunzi 1 (e) pamtunda wokhazikika. Pa B kuchuluka kwa 6 kuyika nkhungu plunger, kuwonjezera ziwiri zokhazikika nkhungu plunger mu C, chokhazikika pini ndodo ndi kudalira nsonga ya reset, pamene kusuntha nkhungu clamping ndege kuika Bwezerani lever kukanikiza mu nkhungu, nkhungu basi kufa kuthamanga kutha, kumbuyo wa mbale kasupe ndiyeno kukankhira pamwamba pachimake, kuchitapo kanthu kulimbikitsa mankhwala kutuluka nkhungu yokhazikika, kuti azindikire kuchotsera deformation deformation.

Pambuyo pa kusinthidwa kwa nkhungu, deformation yowonongeka imachepetsedwa bwino. Monga momwe zasonyezedwera mu FIG.1 (f), zowonongeka pa B ndi C zimayendetsedwa bwino. Mfundo B ndi + 0.22mm ndi mfundo C ndi +0.12, zomwe zimakwaniritsa zofunikira za mzere wopanda kanthu wa 0.7mm ndikukwaniritsa kupanga kwakukulu.

2, Kuthana ndi dzenje la chipolopolo ndi kutayikira

Monga amadziwika kwa onse, kuponyera kuthamanga kwambiri ndi njira yopangira momwe zitsulo zamadzimadzi zimadzadzidwa mwamsanga muzitsulo zachitsulo pogwiritsira ntchito kupanikizika kwina ndikulimbitsa mofulumira pansi pa kukakamizidwa kuti apeze kuponyera. Komabe, kutengera mawonekedwe a kapangidwe kazinthu ndi njira yopangira kufa, pali malo ena olumikizirana otentha kapena mabowo omwe ali pachiwopsezo chachikulu cha mpweya muzogulitsa, zomwe zimachitika chifukwa cha:

(1) Kuponyera kwamphamvu kumagwiritsa ntchito kuthamanga kwambiri kukanikizira zitsulo zamadzimadzi mu nkhungu mwachangu kwambiri. Mpweya womwe uli mu chipinda choponderezedwa kapena nkhungu sungathe kutulutsidwa. Mipweya imeneyi imakhudzidwa ndi zitsulo zamadzimadzi ndipo pamapeto pake zimakhalapo poponyedwa ngati pores.

(2) Kusungunuka kwa gasi mu aluminiyamu yamadzimadzi ndi aloyi yolimba ya aluminium ndi yosiyana. Mu njira yolimba, mpweya umakhala wochuluka kwambiri.

(3)Chitsulo chamadzimadzi chimalimba kwambiri pabowo, ndipo ngati palibe kudyetsa kothandiza, mbali zina za kuponyera zimatulutsa shrinkage cavity kapena shrinkage porosity.

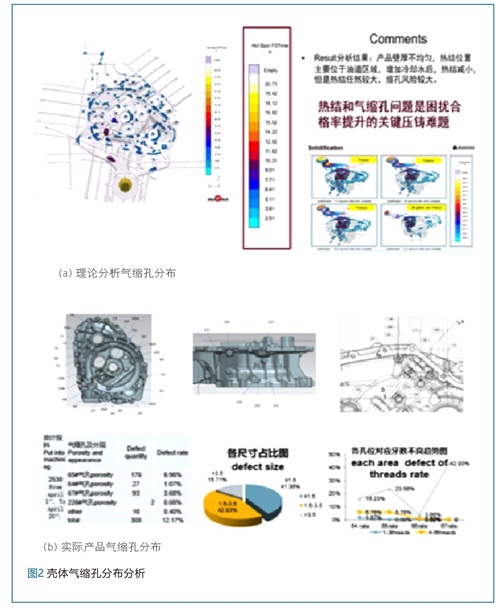

Tengani mankhwala a DPT omwe adalowa motsatizanatsatizana ndi zitsanzo za zida ndi gawo laling'ono lopanga mwachitsanzo (onani Chithunzi 2) : Kuchuluka kwa chilema cha dzenje loyambira mpweya wa chinthucho chinawerengedwa, ndipo chapamwamba kwambiri chinali 12.17%, pomwe mpweya dzenje la shrinkage lalikulu kuposa 3.5mm ndi 15.71% ya zolakwika zonse, ndipo dzenje la mpweya pakati pa 1.5-3.5mm ndi 42.93%. Mabowo opukutira mpweyawa anali okhazikika m'mabowo ena okhala ndi ulusi komanso malo omata. Zowonongeka izi zidzakhudza mphamvu yolumikizira bawuti, kulimba kwapamtunda ndi zofunikira zina zogwirira ntchito.

Pofuna kuthetsa mavutowa, njira zazikuluzikulu ndi izi:

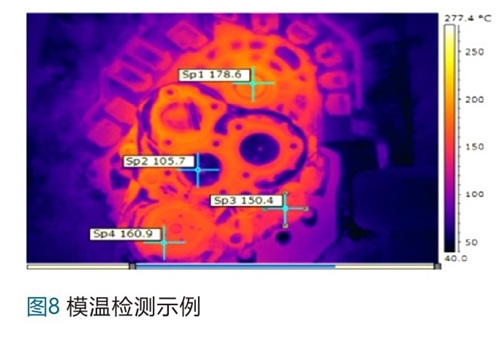

2.1Spot COOLING SYSTEM

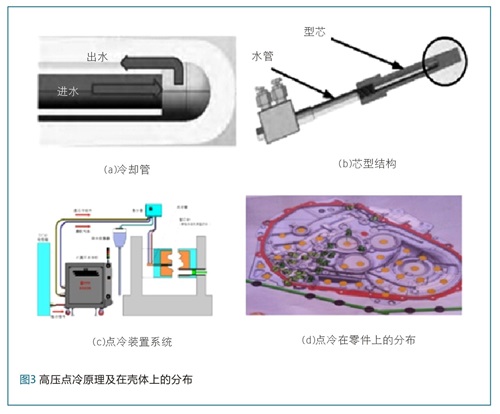

Zoyenera pazigawo zakuya zakuya komanso zigawo zazikulu zapakati. Mbali yomwe imapangidwa mwazinthuzi imakhala ndi zibowo zakuya zochepa kapena gawo lakuya la kukoka pachimake, ndi zina zotero, ndipo nkhungu zochepa zimakulungidwa ndi aluminiyamu yamadzimadzi, zomwe zimakhala zosavuta kuyambitsa kutenthedwa kwa nkhungu, zomwe zimapangitsa kuti zikhale zomata. kupsinjika kwa nkhungu, mng'alu wotentha ndi zolakwika zina. Choncho, m`pofunika kukakamiza kuziziritsa madzi ozizira pa chiphaso cha chakuya nkhungu patsekeke. Mkati mwa pachimake ndi m'mimba mwake wamkulu kuposa 4mm utakhazikika ndi 1.0-1.5mpa madzi othamanga kwambiri, kuti atsimikizire kuti madzi ozizira ndi ozizira komanso otentha, ndipo minyewa yozungulira pachimake imatha kukhazikika ndikupanga wandiweyani wosanjikiza, kuti muchepetse chizolowezi cha shrinkage ndi porosity.

Monga momwe tawonetsera pa Chithunzi 3, kuphatikizapo kusanthula kwa chiwerengero cha kuyerekezera ndi zinthu zenizeni, malo omaliza ozizira ozizira adakonzedwa bwino, ndipo kuzizira kwapamwamba kwambiri monga momwe tawonetsera pa Chithunzi 3 (d) chinayikidwa pa nkhungu, yomwe inkalamulira bwino. kutentha kwa mankhwala m'dera lotentha la olowa, anazindikira sequential solidification wa mankhwala, bwino kuchepetsa m'badwo wa mabowo shrinkage, ndipo anaonetsetsa mlingo oyenerera.

2.2Extrusion wamba

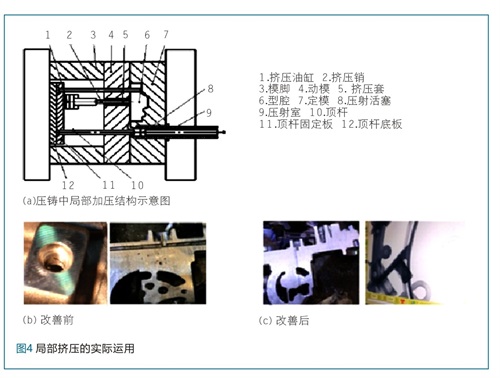

Ngati makulidwe a khoma la kapangidwe kazinthuzo ndi kosagwirizana kapena pali mfundo zazikulu zotentha m'malo ena, mabowo ocheperako amatha kuwoneka m'gawo lolimba lomaliza, monga momwe zasonyezedwera mu FIG. 4 (C) pansipa. Mabowo ang'onoang'ono muzinthuzi sangalephereke ndi njira yoponyera kufa ndikuwonjezera njira yozizira. Panthawi imeneyi, extrusion m'deralo angagwiritsidwe ntchito kuthetsa vutoli. Tsankho kuthamanga dongosolo chithunzi monga momwe chithunzi 4 (a), ndicho anaika mwachindunji mu nkhungu yamphamvu, pambuyo chitsulo chosungunula kudzazidwa mu nkhungu ndi olimba pamaso, osati kwathunthu mu theka-olimba zitsulo zamadzimadzi mu mphako, potsiriza. kulimba khoma wandiweyani ndi extrusion ndodo kuthamanga anakakamizika kudyetsa kuchepetsa kapena kuthetsa shrinkage zibowo zolakwika, kuti apeze apamwamba kuponyera kufa.

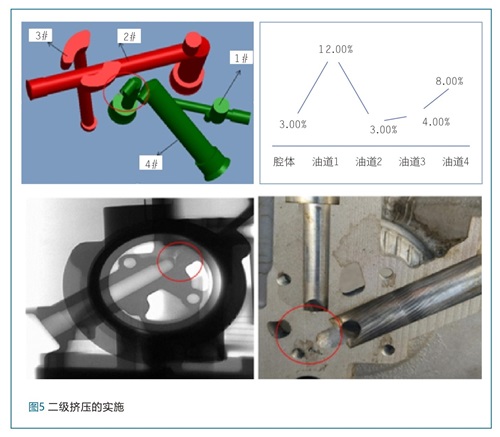

2.3Extrusion yachiwiri

Gawo lachiwiri la extrusion ndi kukhazikitsa silinda iwiri sitiroko. Sitiroko yoyamba imamaliza kuumba kwapang'onopang'ono kwa dzenje loyamba loponyera, ndipo pamene aluminiyamu yamadzimadzi kuzungulira pachimake imakhazikika pang'onopang'ono, gawo lachiwiri la extrusion limayamba, ndipo zotsatira zapawiri za kuponyera ndi kutulutsa zimakwaniritsidwa. Tengani nyumba yama gearbox mwachitsanzo, kuchuluka koyenerera kwa mayeso olimba a gasi anyumba ya gearbox pagawo loyambirira la polojekitiyi ndi osakwana 70%. Kagawidwe ka kutayikira mbali makamaka mphambano ya mafuta ndime 1# ndi mafuta ndime 4# (bwalo wofiira pa Chithunzi 5) monga pansipa.

2.4KUponya RUNNER SYSTEM

The kuponyera dongosolo zitsulo kufa kuponyera nkhungu ndi ngalande amene amadzaza patsekeke ya kufa kuponyera chitsanzo ndi chitsulo chosungunula madzi mu chipinda chosindikizira cha kufa kuponyera makina pansi pa chikhalidwe cha kutentha, kuthamanga kwambiri ndi liwiro. Zimaphatikizapo wothamanga wowongoka, wothamanga pamtanda, wothamanga wamkati ndi makina otulutsa mpweya. Amawongoleredwa pakupanga zitsulo zodzaza zitsulo zamadzimadzi, kayendedwe ka kayendedwe ka madzi, kuthamanga ndi kuthamanga kwazitsulo zamadzimadzi, mphamvu ya utsi ndi nkhungu yakufa imakhala yofunika kwambiri pazigawo monga momwe kutentha kumakhalira kulamulira ndi kulamulira, motero. , dongosolo gating anaganiza kufa kuponyera pamwamba khalidwe komanso chinthu chofunika cha mkati microstructure boma. Kukonzekera ndi kutsirizitsa kwa dongosolo lothira kuyenera kukhazikitsidwa pa kuphatikiza kwa chiphunzitso ndi machitidwe.

2.5ProsiOkukwanilitsa

Die kuponyera ndondomeko ndi otentha processing ndondomeko amene amaphatikiza ndi ntchito kufa kuponyera makina, kufa kuponyera kufa ndi madzi zitsulo malinga ndi chisanadze anasankha ndondomeko ndondomeko ndi magawo ndondomeko, ndi amalandira kufa kuponyera mothandizidwa ndi mphamvu pagalimoto. Zimatengera mitundu yonse yazinthu, monga kukakamiza (kuphatikiza mphamvu ya jakisoni, kukakamiza kwa jakisoni, mphamvu yowonjezera, mphamvu yotsekera nkhungu), kuthamanga kwa jakisoni (kuphatikiza kuthamanga kwa nkhonya, kuthamanga kwa chipata chamkati, ndi zina), Kuthamanga kwamadzi, etc.) , kutentha kosiyanasiyana (kutentha kwachitsulo chamadzimadzi, kutentha kwakufa, kutentha kwa nkhungu, etc.), nthawi zosiyanasiyana (nthawi yodzaza, nthawi yogwira ntchito, nthawi yosungira nkhungu, etc.), kutentha kwa nkhungu (kutentha kwa kutentha, kutentha) mphamvu mlingo, kutentha gradient, etc.), kuponyera katundu ndi matenthedwe katundu wa zitsulo zamadzimadzi, etc. Izi zimatenga gawo lotsogolera mu kufa kuponyera kuthamanga, kudzaza liwiro, kudzaza makhalidwe ndi matenthedwe katundu nkhungu.

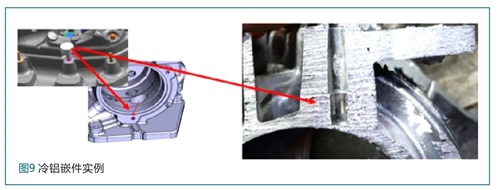

2.6Kugwiritsa ntchito njira zatsopano

Pofuna kuthana ndi vuto la kutayikira kwa magawo otayirira mkati mwa zigawo zina za chipolopolo cha gearbox, yankho la aluminiyamu yozizira idagwiritsidwa ntchito pochita upainiya pambuyo potsimikiziridwa ndi mbali zonse zoperekera komanso zofunikira. Ndiko kuti, chipika cha aluminiyamu chimayikidwa mkati mwa mankhwalawa musanadzaze, monga momwe tawonetsera pa Chithunzi 9. Pambuyo podzaza ndi kulimbitsa, choyika ichi chimakhalabe mkati mwa gawoli kuti athetse vuto la shrinkage ndi porosity.

Nthawi yotumiza: Sep-08-2022